| McMaster University - Chem2OB3 Lab Manual

|

2001 |

Experiment 5: Synthetic Polymers.

References: Brown & Foote, Chapters 23

Pre-lab Questions

1. Draw the structure of benzoyl peroxide

2. Show how benzoyl peroxide decomposes to form two radicals

3. Two different radicals could be produced when an initiator radical

adds to styrene.

Show the structures of two radicals. Which one

is preferred, and why?

4. Draw the structure of poly(methyl methacrylate)

5. Draw the structures of 1,6-hexanediamine, adipoyl chloride and nylon 6-6.

Synthetic Polymers

A polymer (Greek: polys = many, + meros = parts) is a giant or macromolecule made up of repeating structural units. The reaction that unites small molecules called monomers into a polymer is called polymerization. Among the natural polymers important to life processes are starch and cellulose (monomer is glucose), proteins (monomers are amino acids), and nucleic acids (monomers are nucleotides, the phosphate ester of certain N-glycosides).

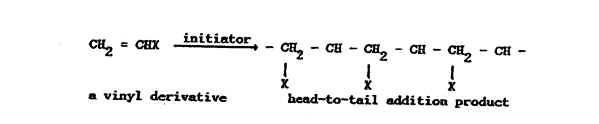

Synthetic polymers can be categorized in several ways, one of which depends on their method of synthesis. Chain growth or addition polymers are formed by a reaction in which monomer units add to another with no other by-products. The most common type are vinyl polymers:

Individual units may be linked in a head-to-tail, head-to-head or random fashion. Examples of the many commercially important vinyl polymers include polyethylene (X=H), polypropylene (X=CH3), polystyrene (X = C6H5), polyvinyl chloride (X=Cl), polyvinyl alcohol (X=OH) or its acetate (X=OCCH3), as well as Teflon (the monomer is CF2 = CF2), and Lucite or Plexiglas (the monomer is CH2 = C(CH3)CO2CH3). Other functional groups, such as dienes, epoxides and aldehydes, can also self-unite to give addition polymers. Copolymers are prepared from the polymerization of a mixture of two or more monomers. Since the ratios of the monomers can be widely varied, copolymers for specific uses can be tailor-made.

Stop Growth or Condensation polymers are formed by reaction with each other of molecules with two or more functional groups (such as glycols, diamines, and dicarboxylic acids), giving long chains joined by many ester or amide links together with the elimination of some small molecule such as water, alcohol, ammonia, or hydrogen chloride. Examples include Nylon (a polyamide), Dacron (a polyester), Bakelite, and polyurethane foams.

In this experiment, the preparation of several polymers in each of these two main classes will be illustrated. Start A1, then B, then continue with A2.

PART A

ADDITION POLYMERS

Polystyrene

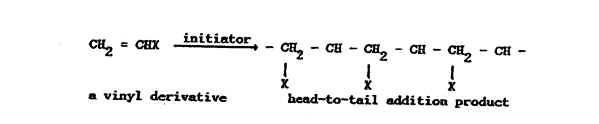

Styrene is most commonly polymerized by a free-radical chain mechanism. The reaction is initiated by a free radical source. In this experiment the initiator is benzoyl peroxide, a relatively unstable molecule which decomposes at 80-90şC with 0-0 bond rupture to give two benzoyloxy radicals:

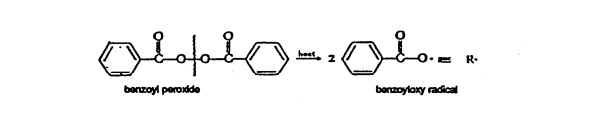

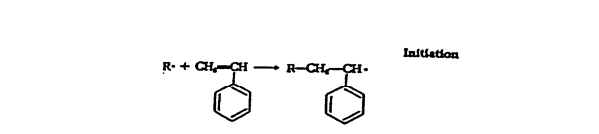

The initiator radicals, symbolized by R add to the C=C bond of styrene monomer to

produce a new, benzyl-type free radical, as shown below:

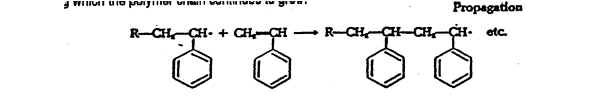

This radical adds to another styrene monomer; the process repeats itself in what is called the propagation step, during which the polymer chain continues to grow:

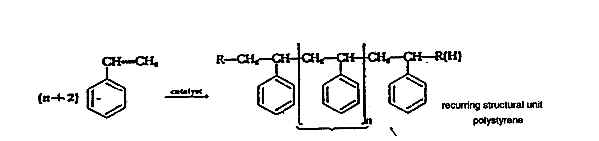

As many as 5000 monomer units may add to one another before the chain is terminated.

Thus, the initiator radical contributes only a very small fraction (perhaps 0.02%)

to the molecular weight of the polymer. Termination may occur by the combination of

two radicals (either both polymer radicals, or one polymer radical and one initiator

radical) by the abstraction of a hydrogen atom, or in other ways. The overall

equation for the polymerization is:

Procedure:

In a fume hood to 10 mL of toluene and 3.64g (4 mL) of styrene in a large test tube, 0.3g benzoyl peroxide. [Care: do not CRUSH this solid]. Place the test tube in a beaker of boiling water for about 1 hour. Cool the tube, and note the viscosity of the solution. Pour the solution slowly and with continuous stirring into a beaker containing 100 mL of methanol. Collect the white precipitate of polystyrene on a Buchner funnel (vacuum), and wash the precipitate twice with 25 mL of methanol. Spread the polymer on a paper towel to dry. Melt a little in a small test tube, and draw a fibre from it by means of a glass rod or matchstick brought in contact with the melt and withdraw slowly. Describe the fibre (brittle?).

Methyl Methacrylate Polymer

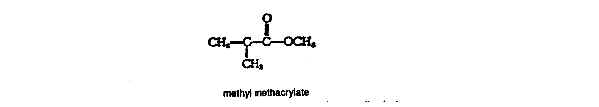

The clear, colourless plastic Lucite or Plexiglas is made by polymerization of the

vinyl ester methyl methacrylate:

In this experiment, benzoyl peroxide will be used to initiate a free radical chain polymerization of the monomer. A trace of a weak base is added to neutralize any acid present. A control, kept at room temperature, will be compared with a sample polymerized at boiling water temperature.

Procedure:

To 10 mL of freshly distilled methyl methacrylate (d=0.936), add 1 drop of N,N-dimethylaniline and 0.1g of benzoyl peroxide. Set 5 mL of the mixture aside as control, and place a test tube containing the rest of the mixture in a boiling water bath. At 2-minute intervals, transfer one drop of the hot reaction mixture to a test tube containing 10 mL of methanol, and note whether it dissolves. Observe the change in solubility as the molecular weight of the polymer increases during the reaction. After 15 minutes, cool the tube and dissolve the polymer in a 10-15 mL of acetone. Pour the polymer solution with vigorous stirring into 100 mL of water. Collect the precipitated polymer on a Buchner funnel (vacuum), dry and examine it.

Now, examine the control, by adding one or two drops to 10 mL of methanol. Note whether any polymer precipitates.

Question:

1. Explain why the portion of the reaction mixture left at room temperature (in Part A-2) formed little if any polymer.

PART B

CONDENSATION POLYMERS

Bakelite:

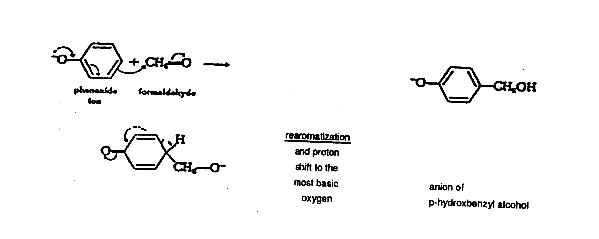

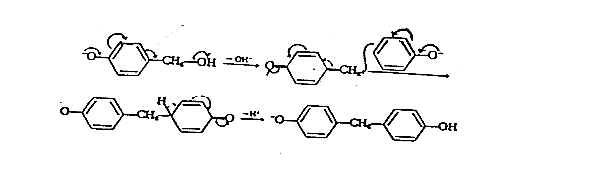

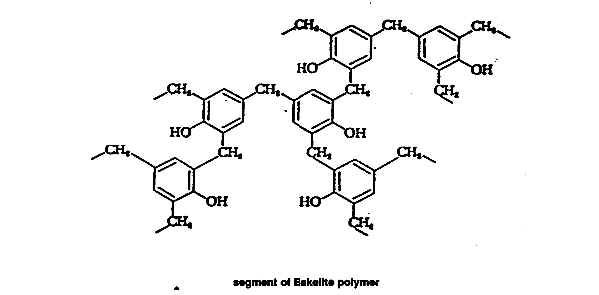

Phenol and formaldehyde react, in the presence of base, to form a three-dimensional

polymer -- Bakelite -- suitable for making many molded articles. The reaction

sequence is:

Under carefully controlled conditions, o- or p-hydroxybenzyl alcohol may actually be

isolate. Usually, the reaction goes further, leading to polymer:

In this manner, pnenol molecules become linked to one another at ortho or para

positions by methylene groups.

Procedure:

In a fumehood place 0.1 g of phenol, 0.3 mL of concentrated ammonium hydroxide, and 4 mL of 40% aqueous formaldehyde solution in a test tube. Warm the tube slightly to melt the phenol, and shake the tube to obtain a homogeneous solution. Place the tube in a boiling water bath for 1-1/2 hours. Cool the tube, and dislodge and examine the polymer.

Nylon 6-6

Under appropriate conditions a variety of dicarboxylic acids will react with diamines to give polyamides and water. These polymers can hydrogen-bond with each other to give strong fibres.

Procedure: Pour 10 mL of 5% aqueous solution of 1,6-hexanediamine into a 50 mL beaker. Add 20 drops of 10% sodium hydroxide solution. Tilt the beaker slightly, and carefully pour down the wall 10 mL of a 5% solution of adipoyl chloride in hexane, trying to avoid mixing or turbulence. A polymer film will form at the interface. Grasp this with a piece of hooked metal or pair of tongs. Fasten it to a large test tube or narrow beaker, and slowly rotate it, to draw out a polymer fibre.

Finally, rinse your fibre with water and dry on a piece of paper towel. Comment on its properties.

| Go to: | Instructions for Printing this Document Chem2OB3 Home Page. |

May 28, 2001